13 Apr Reflective Runway Markers Solution at Private Airport for 24/7 Operations

Application: Reflective Marking Solution for 24/7 Operations

Products:

- Retroreflective Runway Marker Surface Model-324

Location: New Mexico, U.S.A.

Date: 2021

Synopsis

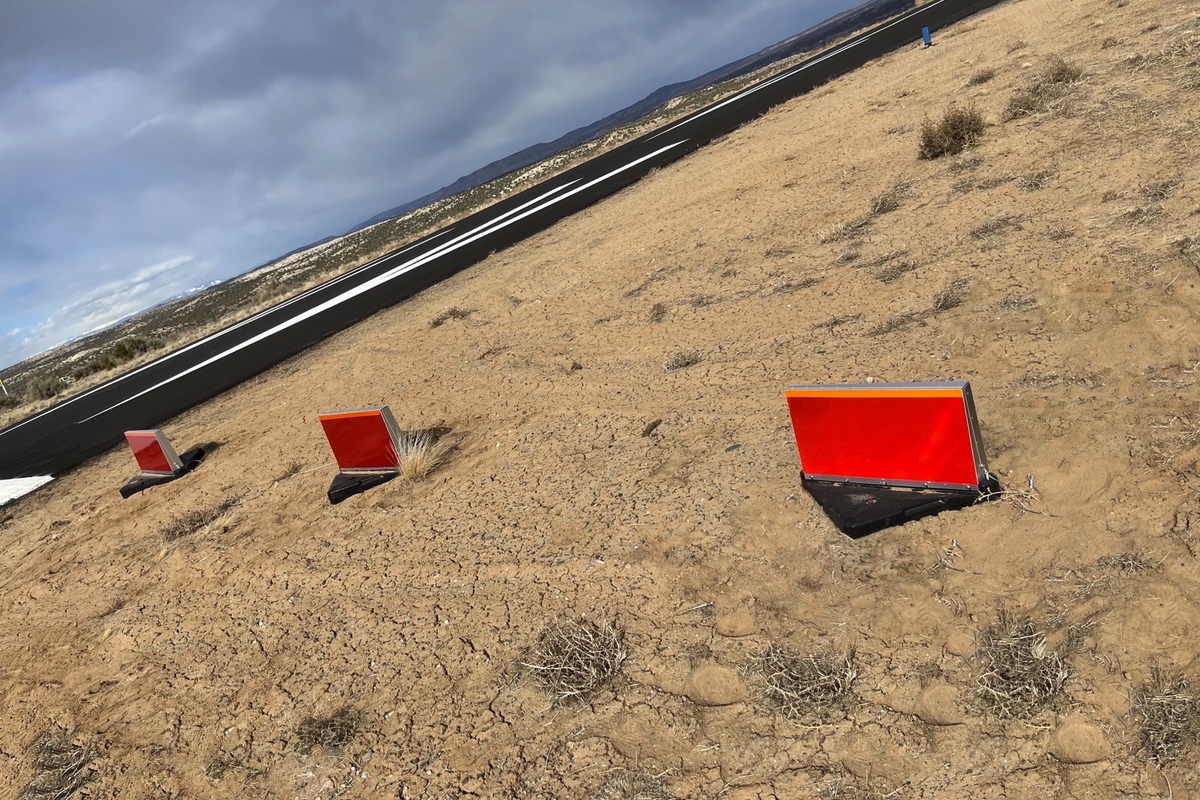

Reflective Runway Markers – Aviation Renewables designed and supplied a refurbishment kit for a runway using Model 324 Reflective Runway Markers. The airport had been using the markers for 2 decades, and needed a specially designed reflective sheath in order to extend the life of the existing markers.

Challenge

The client is a municipal airport in the U.S.A. Two decades ago, they invested in a reflective marking solution with a Passive Approach Slope Indicator to enable 24/7 operations at their airport. The FAA L853 reflectors were faded after 20 years of being exposed to the sun and were in need of refurbishment. The bases, however, were still in good condition and could remain in place. The airport sought help from Aviation Renewables to design, manufacture and deliver new retroreflective sheaths in order to continue using their existing marker bases having a complete service life for other 15 years.

Solution

The existing markers used HDPE bases that were still in good condition. The bases were anchored to the ground, so it made sense to keep the anchoring in place and replace the reflective panel alone. Aviation Renewables provided new reflective sheaths that comply with L853 standards. The reflective sheeting on the aluminum sheath is micro-prismatic conspicuity material that complies with ASTM D4956. The thin, flexible sheeting has a unique appearance featuring a printed triangular white line pattern. It provides superior visibility and conspicuity to oncoming aircraft which results in improved safety.

The aluminum sheaths will not corrode, and we anticipate them having a service life of 15 years. The UV and solvent resistant coatings ensure durability which allows for rugged outdoor use. Conspicuity-grade material like this is typically 6 or 7 times more reflective than a comparable color in an engineering-grade reflective tape since prism technology is used instead of glass beads, which greatly increases the visible range of the runway markers. The sheaths shipped with new tethers to ensure FOD control in case of accidental damage to the marker. The airport installed the sheaths on the existing bases with simple tools, and was able to conduct the retrofit without need for closure of the runway.

View the complete Project Report and find more about Reflective Runway Markers here.

Sorry, the comment form is closed at this time.